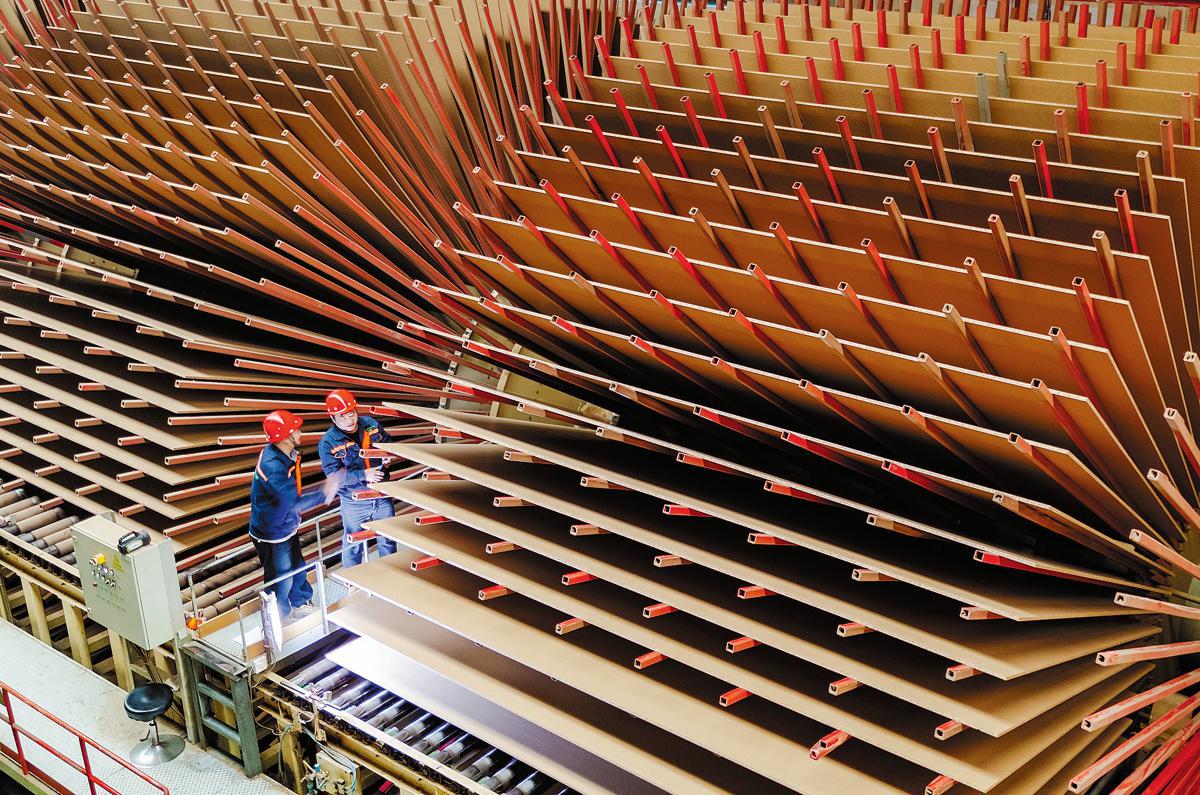

Workers take measurements of boards made from straw at a production line of Wanhua Hexiang Board in Hubei province, on Dec 2. CHINA DAILY

Crop straw in many rural areas across China used to be commonly used for cooking or feeding livestock. However, with the decline in rural populations and the increasing prevalence of gas stoves and mechanization in rural China, straw has been relegated to waste.

However, in Jingmen, Hubei province, this waste has undergone a remarkable transformation, evolving from mere refuse into a valuable resource. Not only has it facilitated carbon emission reduction, but it has also played a pivotal role in fostering economic growth.

Straw remnants have been ingeniously repurposed into green materials used in the production of furniture.

At the foot of Shengjing Mountain in Jingmen's Dongbao district lie 32 cottages of various shapes and sizes. The builder of the cottages claims all materials used in their construction are "grown from the earth".

At first glance, all appear as if these cottages are built with standard materials, but on closer inspection of the floor, for example, the structure resembles a three-layer "sandwich".

"These are eco-friendly straw boards, and they are primarily made from agricultural and forestry residues," said Yang Zhijian, general manager of Wanhua Hexiang Board (Jingmen) Co, the builder of the cottages.

The middle layer is made from tree branches and the outer two are from straw, which work well as natural flame retardants and moisture barriers, he said.

Jin Peng, assistant to the chairman of the company, said that using straw in board manufacturing is cost-effective and contributes to reduced carbon emissions.

On average, the company uses 600,000 to 700,000 metric tons of straw a year, he said. Compared with other types of agricultural and forestry residues, the price per ton of straw is about 40 yuan ($5.49) cheaper.

Quoting a calculation by the Guangzhou Institute of Energy Conversion of the Chinese Academy of Sciences, he said the company can annually reduce equivalent greenhouse gas emissions by 384,700 tons of carbon dioxide.

He said the company, launched in 2016, can now produce 350,000 cubic meters of boards for furniture manufacturing each year.

Wanhua Hexiang is just one of 60 companies that compose a complete industrial chain transforming straw into custom-made furniture in Dongbao's agricultural industrial park.

The annual output value of the park has reached almost 8 billion yuan, according to the local government.

Jin said the local government has played a crucial role in setting up a robust straw collection system to guarantee a steady supply to the industrial park.

With the establishment of four township-level centers and 20 village-level collection points, Jin highlighted that "the Dongbao district government has been diligently working toward creating a comprehensive straw collection and storage system that encompasses all areas within its jurisdiction".

"This initiative has effectively tackled all obstacles related to straw collection and storage," he said.

With the support of the Dongbao district government, the Chusheng Agricultural Machinery Service Cooperative was established in 2017 in Ziling township. To date, the cooperative has received government subsidies totaling 710,000 yuan, most of which are for the construction of storage facilities and the procurement of machinery, including balers, according to Zhao Tianzhu, the director of the cooperative.

The cooperative serves over 1,000 households collectively owning nearly 270 hectares of farmland. The price of straw was between 400 and 500 yuan per ton last year, Zhao said.

"Previously considered waste, straw was crushed and returned to the field by farmers... It is now recognized for its economic benefits and potential to boost farmers' income," he said, adding the straw collection business generated over 500,000 yuan in income for the cooperative, machinery operators and farmers last year.

Contact the writers at houliqiang@chinadaily.com.cn