A researcher tests android "Walker X" at a science company in Shenzhen, Guangdong province, in June. MAO SIQIAN/XINHUA

"Made in China" once evoked images of low-cost, labor-intensive commodities. Many years later, the tag stands for advanced innovations such as electric vehicles and drones.

A major participant in this evolution is the Guangdong-Hong Kong-Macao Greater Bay Area, a region in South China made up of 11 cities and 87 million residents. The GBA has not only mirrored the nation's transformation from a world factory to a smart manufacturing hub, but has also incubated 70 unicorn companies — startups valued at over $1 billion each.

So influential has the rise of this particular region of South China been, that it has developed its own epithet — products made here are not just "Made in China" they're "Made in the GBA".

In Guangzhou's newly developed Nansha district, Kenny Oktavius, the young CEO of the tech startup PointFit Technology, showcases his company's latest innovation — a super-thin chip designed for use in sports.

"We can stick it to the skin without any adhesive. So, this will definitely be much (more) convenient, especially for athletes who don't like bulky wearables," he said.

The tracker, which monitors muscle health through sweat analysis, is designed and produced within the GBA.

An Indonesian from Jakarta, Oktavius came to the Hong Kong University of Science and Technology in 2015 for his bachelor's degree in chemical and biological engineering, later proceeding to postgraduate studies.

Mentored by professor Gao Ping, a chemical engineering specialist, Oktavius launched PointFit Technology in 2020 with two research partners, based on an idea of a sweat-sensing wearable device he had developed during his senior-year research.

The product quickly gained the industry's attention, winning several health tech awards and securing a spot on Forbes Asia's 100 To Watch list in 2022 — a roster for small companies recognized for their trailblazing solutions to global challenges.

The GBA's manufacturing expertise has been instrumental in the rise of the young team.

Initially, Oktavius sought out a Taipei manufacturer for production. While functional, the prototype's quality was subpar. Later, a better-equipped manufacturer in Shenzhen, offering a shorter production cycle and superior quality, proved to be the solution.

"Recently, we just produced 300 of these (chips) in one day," Oktavius said, clearly impressed.

Jack Chen, chief operating officer and co-founder of PointFit Technology, added that GBA factories are uniquely open to innovation.

"They are willing to accept new ideas and modify their machines if the existing ones cannot realize our demands," he said.

Professor Gao expressed full confidence in the practical application of the ultra-high-molecular nanomembrane developed by her students, a material previously confined to laboratory research.

"In the GBA, we can look up at the sky, and work down-to-earth," she said, referring to the region's robust industrial supply chains that facilitate the industrialization of "dream big" research projects.

Ambitious scientists like Oktavius and Chen, thriving in Hong Kong's academically rich environment — home to five of the world's top 100 universities — are becoming a more significant driving force behind the region's innovative prowess. Supported by regional government funds, they are following in the footsteps of DJI and SenseTime — which both originated on Hong Kong campuses — in aiming for global enterprise leadership.

Furthering their ambitions, Oktavius' team has established a subsidiary in the Hong Kong & Macao (International) Youth Entrepreneurship Hub in Guangzhou's Nansha district, to better streamline their supply chain integration.

This hub is a cradle for about 74 startups across diverse sectors such as internet technology, healthcare, advanced materials, green energy and education.

Oktavius points out the region's potential as a global smart manufacturing powerhouse. "That's essentially the edge that the GBA startup community has."

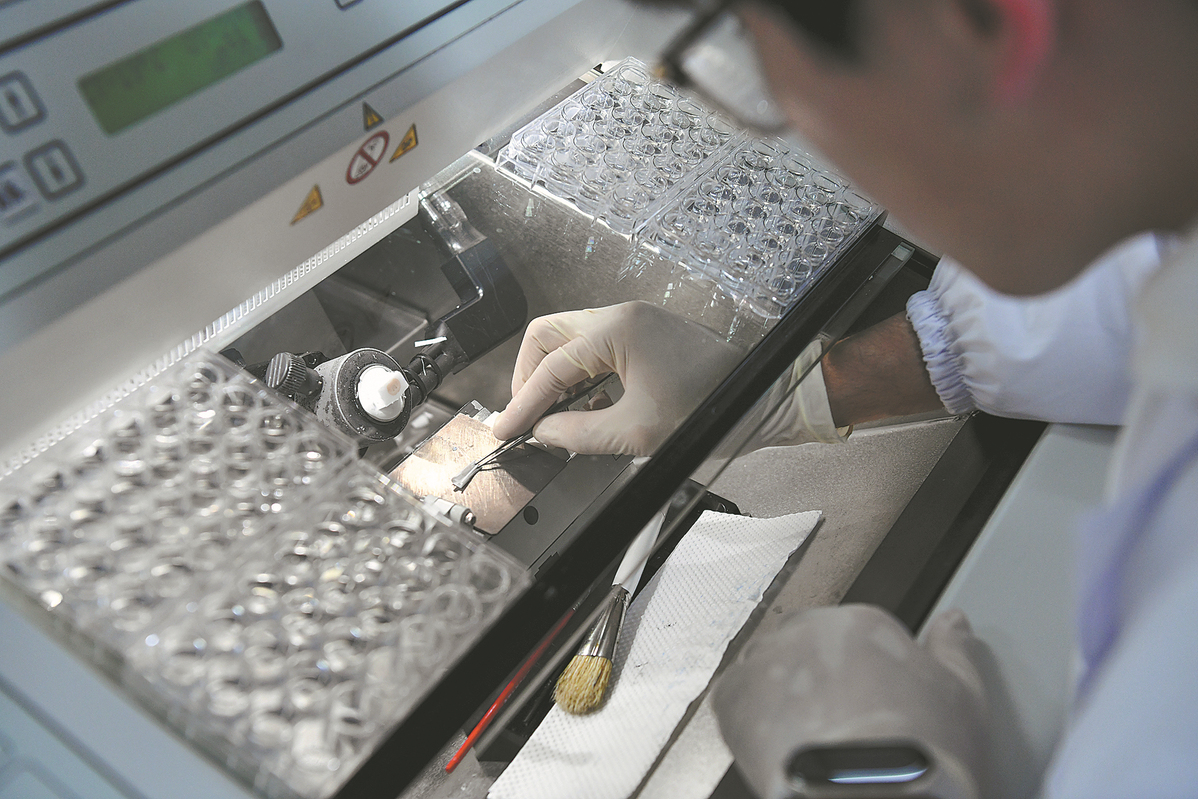

A researcher prepares samples for an experiment at the Brain Science Infrastructure in Shenzhen, Guangdong province, in November. LIANG XU/XINHUA

Legacy continues

Li Chen, an associate professor at the Centre for China Studies of the Chinese University of Hong Kong, views the success of the GBA as a natural outcome of its inherent strengths.

"The GBA has a large cluster of world-leading universities and research institutes. And we have a very good innovative ecosystem," he explained.

In the meantime, he highlighted the GBA's strong cultural legacy — an enduring willingness to embrace risk and pursue unconventional business avenues.

"There's a strong continuity in terms of the entrepreneurship culture in this sphere," he said.

Shenzhen and Zhuhai in Guangdong province were among China's first special economic zones established during the country's reform and opening-up in the late 1970s. Despite their transformative changes over the past decades, the spirit of urban pioneering persists.

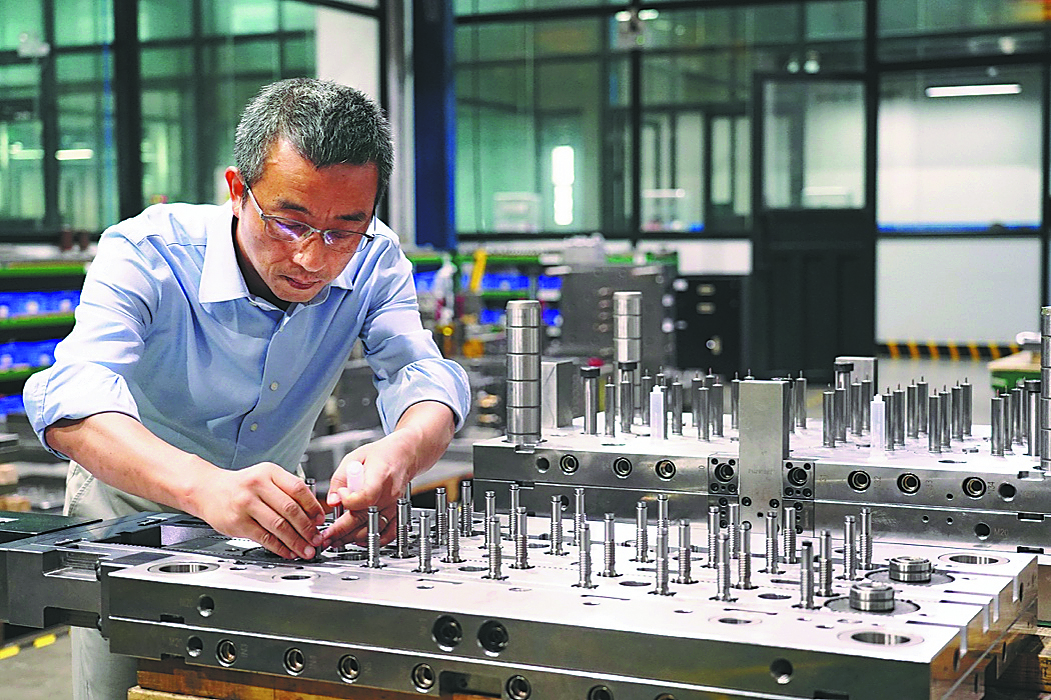

Take the example of Felix Choi Chun-kit, a Hong Kong industrialist and CEO of Hongrita Holdings. His mold production company, founded in 1988 in Hong Kong, has witnessed the GBA's seismic shift.

In 1993, Choi moved his operations to Shenzhen, then a hub for labor-intensive industries.

He recalled the early challenges posed by Shenzhen's underdeveloped industrial supporting facilities.

"Even for something as simple as a screw, we had to source it from Hong Kong and bring it to Shenzhen," he said.

Today, the GBA's industrial capabilities are all-encompassing. "We can find all the components that we need locally with very competitive quality and price," he said.

Choi has since inaugurated a digital, intelligent workshop in his Zhongshan facility, where the production line operates autonomously, with high-end robots gliding along preset routes.

From 2018 to 2022, Hongrita's average annual production value per employee increased by about 37 percent, reaching an annual output value of 600 million yuan ($86 million).

With manufacturing cycles averaging 45 seconds, every second saved translates into an additional 4 million yuan in benefits.

The recent opening of the Shenzhen-Zhongshan Link, which cut travel time between the two cities from two hours to just 30 minutes, has further streamlined operations.

Technological advancements and process optimization have reinforced the confidence of manufacturers like Choi. "In the end, precision molds will be labeled 'Made in GBA'," he said.

Looking ahead, Choi aims to transform Hongrita into one of the "lighthouse factories", a term coined by the World Economic Forum to designate benchmark manufacturing sites that integrate cutting-edge technologies with efficient and sustainable practices.

In 2023, the forum's "lighthouse factories" list included 62 Chinese factories, with eight located within the GBA.

Felix Choi Chun-kit, CEO of Hongrita Holdings, oversees the production line at the company in Cuiheng New Area, Zhongshan, Guangdong province. [Photo provided to CHINA DAILY]

Innovation investment

The stories of PointFit Technology and Hongrita reflect a common strategy in the GBA — adapting to change and investing to drive it.

In 2022, the GBA's annual research and development spending soared to 447.8 billion yuan, accounting for 3.4 percent of its GDP. This surpassed the figures of global tech powerhouses like Germany (3.14 percent) and Japan (3.26 percent).

According to the Global Innovation Index 2023, the Guangzhou-Shenzhen-Hong Kong technology cluster ranked as the world's second-most active cluster in terms of patents and scientific publications for four consecutive years.

These strides align with the strategic vision outlined in the recent resolution of the third plenary session of the 20th Central Committee of the Communist Party of China, which supports leading urban clusters to serve as engines of the nation's high-quality development.

In the new development stage, CUHK professor Li highlighted the supply chain and new quality productive forces as a key concept for the GBA.

"Now we are seeing a new configuration of the supply chain that can capture more systemically, more efficiently the changing demands" of both Western and domestic markets, he explained.

Companies have been empowered to craft more efficient production systems, drawing on diverse resources spread throughout the region.

Regarding new quality productive forces, Li emphasized that they include novel technologies, new business models, and emerging industries.

He stressed that they also involve modernizing traditional industries through innovative operational methods, particularly in automation and digitalization.

"We should not only strengthen the development of emerging strategic, high-tech sectors, but also use the latest IT technologies, digital technologies, to increase the productivity of traditional industries, and traditional manufacturing," he said.

Contact the writers at shixiaofeng@chinadailyhk.com